Light Transmission Method for Green Veneer Moisture Sorting

Accurate green veneer sorting has a significant impact on both veneer dryer productivity and final veneer quality.

Accurate green veneer sorting has a significant impact on both veneer dryer productivity and final veneer quality.

Current Methods

Currently, the moisture content of green veneer is measured using industrial radio frequency (RF) sensors installed beneath the veneer ribbon. In most installations, several RF moisture readings are averaged, and a moisture grade is assigned to each sheet, effectively Based on these RF moisture readings -- typically submitted as an average moisture valuesorting the veneer into three general categories: sap, light sap, and heartwood.

However, laboratory testing has shown that the existing RF sensor head technology requires a positive contact with the veneer in order to generate accurate results. Furthermore, a gap as narrow as 1 mm between the sensor head and the veneer sheet will cause inaccurate moisture readings by as much as 50%! With the high speeds of green-end conveyors, it is virtually impossible to maintain continuous, direct contact between the wavy veneer and the RF heads. This means that very inaccurate readings often occur, especially within the wetter "sap" and "light sap" veneers, where RF sensor heads have been shown to be highly inaccurate. These inaccurate moisture readings lead to mis-sorted veneer, resulting in reduced productivity and quality control issues futher down the line.

Consider also that each 1% loss in dryer production -- caused by mis-sorted veneer -- is costing the average mill, conservatively, an extra $150,000 to $180,000 per year. And given that 80% of a mill’s yearly energy costs are consumed by veneer drying, these losses can only be expected to rise as the current trend of escalating energy costs continues.

A New & Better Approach

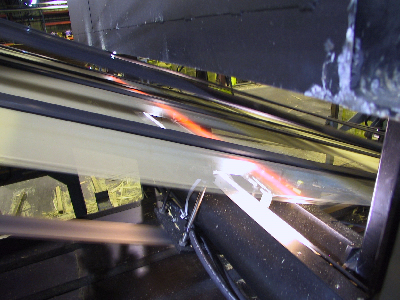

An alternative technology exists which effectively overcomes all of these limitations of the traditional RF sensor technology. By utilizing leading-edge advancements in both LED light transmission, and CCD camera sensitivity, this new approach offers a highly accurate, non-contact method for green veneer moisture measurement.

Using tightly controlled pulses of a high-output LED array, the green veneer is effectively ‘candled’, revealing the moisture content locked within the entire sheet. A high resolution visual image is captured using a critically aligned and highly sensitive CCD camera, and this image data is then passed forward through a complex series of image processing algorithms. The average and peak moisture content is instantly calculated for each sheet, and based on this information, each veneer sheet is assigned a specific moisture value. This assigned value effectively becomes the ‘finger print’ for that particular sheet, which in turn allows the sheet to be very accurately sorted to a standard set of criteria specifically formulated for each species and peel thickness, or as required by any number of other mill-specific customization criteria. With this highly accurate moisture information, each sheet can then be sorted into any number of bins, with absolutely no limits to the number of sorts available.

Continue...